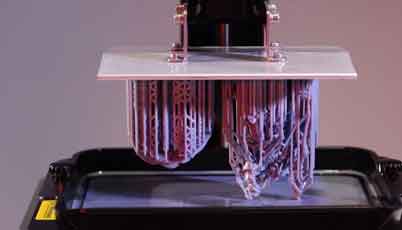

The resin printing process is faster and easier to set up than 3D printing, but there are some disadvantages. First, the resolution of the prints is limited. This is because of the complicated parameters of resin printing. You need to pay close attention to the details so that you can produce a high-quality print. The resin that you use will determine the level of detail that you can achieve. For example, a resin printer can produce objects with a resolution of up to 100 microns.

Best Resin Printers Available Today

In addition to the cost, the resin printer requires a lot of maintenance, which can add up quickly. But the cost of an industrial-grade unit is still relatively low. The cost of photopolymer can reach thousands of dollars. This technology is also more precise than the other methods. The disadvantage of using the resin printing technique is that it requires a post-print curing process, but the advantages outweigh the disadvantages.

Resin Prints Offers Better Quality

A resin printer also produces better quality prints than other techniques. In general, a photosensitive resin is easier to load into the printer than molten plastic. The result is a more precise and aesthetically pleasing print. A metal 3d printer is also easier to use when engraving fine details. It leaves a thin layer line that is virtually invisible, whereas a model made of molten plastic will leave a layer mark that will be noticeable to others.

Uses Resin Printing Technology

The advantages of resin printing outweigh the disadvantages. For example, the cost of a resin printer is higher than for other 3D printing techniques. However, it is much more affordable for mold masters and prototypes, and can produce more complex shapes and patterns. Finally, the resin is more resistant to water than plastic, which makes it ideal for watertight applications. The resin is also stronger and supports more objects on the build platform, and the parts appear to “fly” without any imperfections.

Top Disadvantages

The disadvantages of resin printing machines are limited build volumes. It is not possible to produce large-scale objects with a resin printer, which means the model must be small. It is more expensive to produce high-quality models, but the resin is cheaper than other 3D printing techniques. The advantage of a resin printer is that it can create more detailed and durable objects than a traditional machine, and it can also be faster and safer than other types of 3D printing.

Resin Printers Are More Expensive

A resin printer is more expensive than a 3D printing machine, but it is worth the price. It is more accurate than FDM and SLA machines and offers a greater range of materials. But the disadvantages of resin printing include the fact that they require more maintenance than other technologies. Lastly, resin printers are more expensive than FDM and SLA machines. In addition, they are not as versatile as other 3D printers.

Conclusion

The main disadvantage of resin printers is that they are expensive when used in end-use products. They are cheaper for prototypes and mold masters. The downside of a resin printer is that the materials used in these machines are not very environmentally friendly, and may contain lead, which can affect the environment. The downside of resin printing is the fact that the resin is hazardous to the environment. If it is not used responsibly, it can cause health problems.